NACHI-FUJIKOSHI CORP.

Top page > Product Info. > Machine Tools > Skiving machining center for Gears > Skiving machining center for Gears GMS200

Machine Tools

Main text

Skiving machining center for Gears GMS200

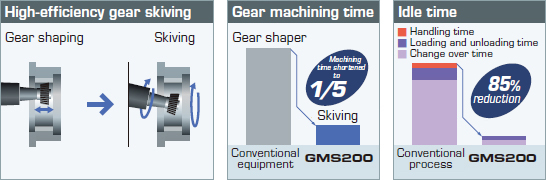

High-efficiency gear skiving and integrated process

remarkably reduce machining time

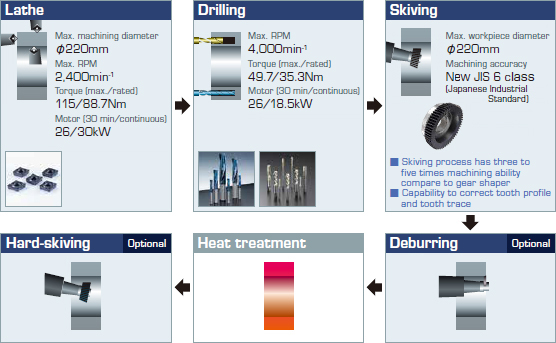

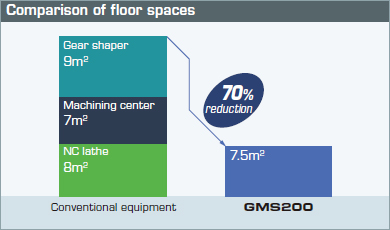

Multiple process in one machine

To achieve compact production lines by reducing floor space

with 3 roles in 1 machine

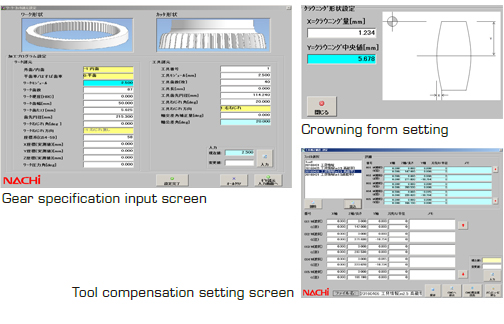

Superior workability and operability

Interactive operation screen for skiving (optional)

- Crowning process and run-in amount modification function (initial mode)

- Newly added tool compensation setting and workpiece coordinate system preset

All machining conditions for skiving can be set

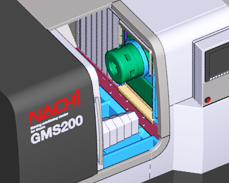

Ceiling opening door

- Aperture dimension : 600mm

- Easy access to jig and simple loading & unloading of workpieces

- Workpiece installation

height : 1,170mm

Reduced machine height for better view

- Contribute to environment improvement in factory

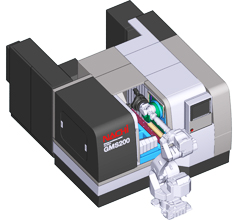

The design for auto loading system with robots

Machining application

Internal gear

External gear

Spline

Skiving cutter for hard-skiving

- Achieved high precision of workpieces after heat treatment

- The design reduces noise from reducer

- NACHI's original DuAl Hard coating for hard skiving

- Stable machining without rake face coating

Combine with NACHI robots

Combine with NACHI robots for auto loading system

MZ04

EZ03

MZ12